Press Ceramics Definition

The device used in ceramics to fire bake our ceramic art work.

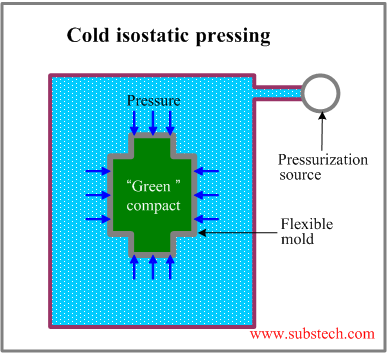

Press ceramics definition. Once the mold is removed the piece produced is a uniform replication of the inside of the mold similar to casting with metalwork. A ceramic material is an inorganic non metallic often crystalline oxide nitride or carbide material. For example clay has chemically bonded water in it which will cause it to slake down disintegrate when a dried clay object is put in water. Some elements such as carbon or silicon may be considered ceramics ceramic materials are brittle hard strong in compression and weak in shearing and tension.

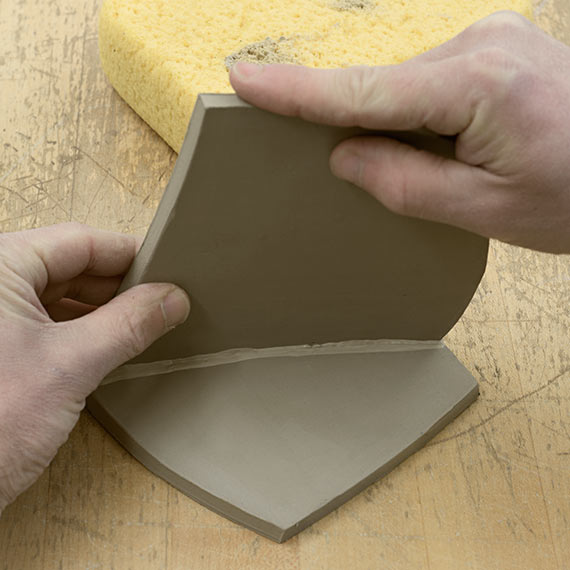

Clay press definition is a filter press used for expressing excess water from slip in pottery making. They withstand chemical erosion that occurs in other materials subjected to acidic or caustic environments. A sharp instrument used to cut pierce and incise designs on clay. Clay that has been shaped and.

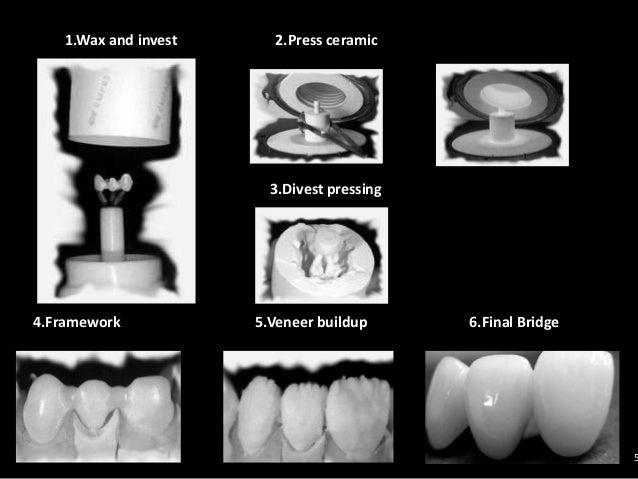

Press mold definition is a cast iron mold used in glassmaking. Once heated fired to between 660 and 1470 f 350 and 800 c the clay is converted to ceramic and will never dissolve again. If not done thoroughly air bubbles will cause the clay. Ips e max press lithium disilcate glass ceramic ingot for the press technique ips e max zirpress fluorapatite glass ceramic ingot for the press on technique ips e max cad lithium disilcate glass ceramic block for the cad cam technique.

Ips e max is an all ceramic system that consists of the following five components. Technically ceramics are those things made from materials which are permanently changed when heated. Made from clay that has been shaped and then baked until hard. To wedge means to cut clay into manageable pieces and push and press on clay to expel all air bubbles trapped in the clay.

Yagi studio getty images. In pottery press molding refers to the process in which clay is forced into a mold in order to take on a certain shape.