Precipitation Powder Processing Ceramics

Ceramic powders for other applications sol gel processing of colloids nuclear industry liquid chromatography abrasives melt solidification abrasives ceramic fibres manufacture blow spin process extrusion or draw process crystallization method vapour phase routes cvd chemical transformation of precursor fibre.

Precipitation powder processing ceramics. This book covers both the processing and the synthesis ofceramic powders in great depth and is indeed the only up to date comprehensive source on the subject available. Ceramic powder synthesis and processing are two of the most important technologies in chemical engineering and the ceramics related area of materials science. Of the apparatus 42 46 in these cases the powder processing or sintering technique can add contaminants which can be retained in the dense ceramics and impact the bulk properties. 3 2 ceramic powder processing 2 milling techniques 7 33 3 3 ceramic powder processing 3 ssr co precipitation spray drying sol gel process hydrothermal synthesis rsp 14 34 3 4 ceramic powder compaction and sintering 12 27.

The influence of preparation condition on properties of pp powder was investigated. Most often pug mills are the preferred piece of machinery used in this step of the process when dealing with dry mixes. Powder processing shaping and firing ring 1996. 3 3 ceramic powder processing 3 ssr co precipitation spray drying sol gel process hydrothermal synthesis rsp 14 34 3 4 ceramic powder compaction and sintering 12 27 3 5 fast sintering 11 36.

A typical brick manufacturing process figure 20 1 starts with the raw materials being shipped from different locations to the manufacturing plant where they are stocked for later use. The experimental results show that the optimal preparation conditions are as follows. Therefore there exists an opportunity to develop a processing route free from additive based green body formation and car bon based high pressure sintering. It is also important to add binders or plasticizers as well.

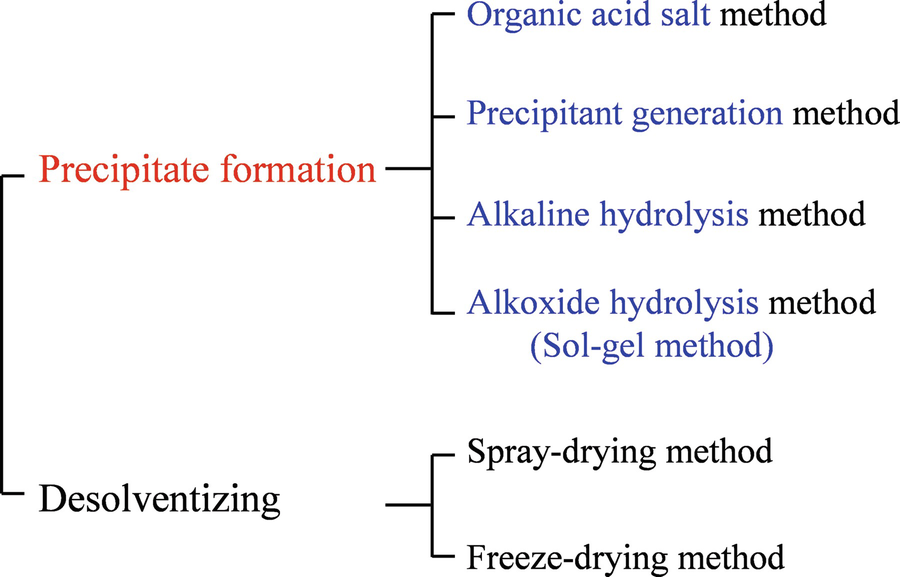

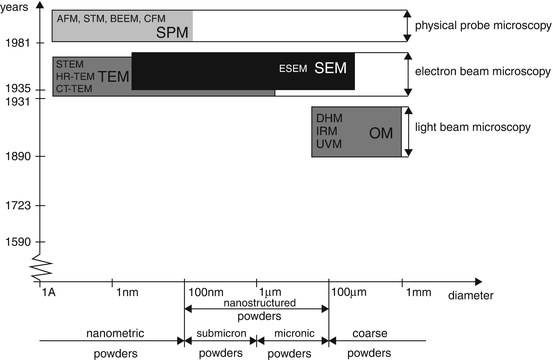

Powder synthesis and subsequent processing have a large influence on the final properties of ceramic and powder metallurgy materials. Dissolution temperature being about 166 xb0 c. Ema 5646 ceramic processing zhe cheng 2015 2 powder preparation powder synthesis via precipitation from solutions precipitation production of ceramic powder and or precursors e g oxylates from precipitation from uniform solution via certain reactions homogeneous nucleation in most cases. Therefore the selection of the appropriate powder processing route determines to a large extent the results that can be obtained in the final product.

Brick manufacturers generally are located.