Ppt Ceramics Processing

Properties of ceramics classification of ceramics ceramic raw material fabricating and processing of ceramic application of ceramics 1 glasses 2 clay products 2 1 structural clay product 2 2 whitewares 3 refractories.

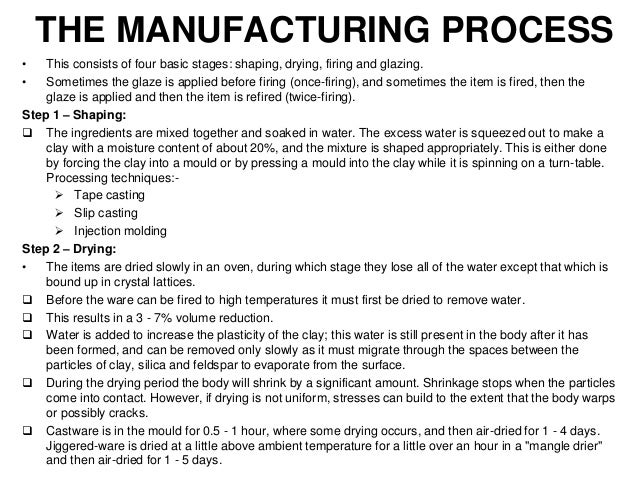

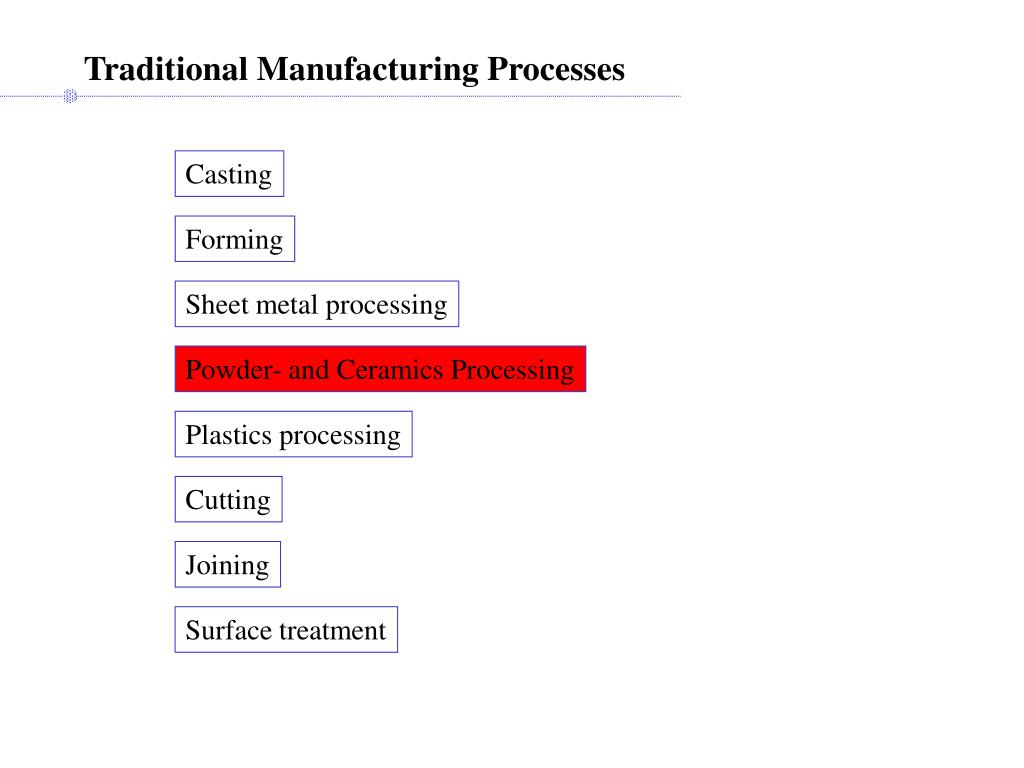

Ppt ceramics processing. Processing of ceramics most traditional and engineering ceramic products are manufacture by compacting powders or particles into shapes that are subsequently heated to a high enough temperature to bond the particles together. The 3 basic steps in the processing of ceramics by the agglomeration of particles are. 3 1 fireclay 3 2 silica 3 3 basic refractories 3 4 special refractories 4 abrasives 5 cements 6. Most often pug mills are the preferred piece of machinery used in this step of the process when dealing with dry mixes.

The purpose of this thermal processing is to provide additional drying to vaporize or decompose organic additives and other impurities and to remove residual crystalline and chemically bound. Ppt provides processing development and custom powder processing services for the leaders in ceramics inorganic materials technology. Because of their inherent brittleness ceramics cannot be formed by rolling extrusion drawing etc their high melting temperatures also add restrictions on the use of casting techniques. Outline of topic 3.

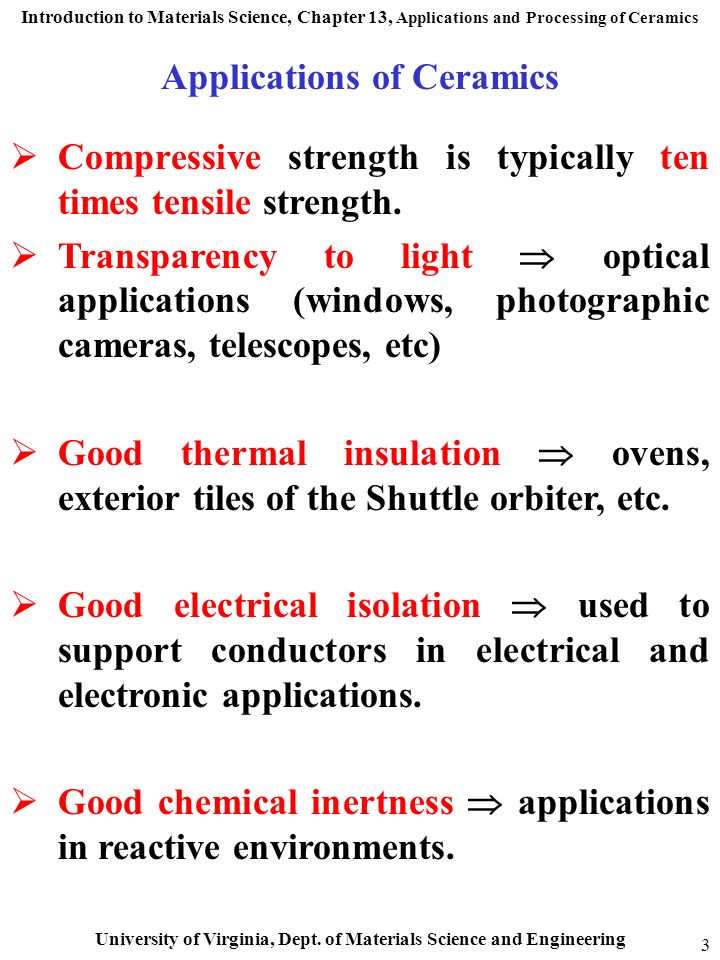

Ceramic materials applications and processing classification of ceramic materials on the basis of application glass clay product refractory. Processing services volume powder production that ensures your competitiveness. Mixing to obtain a more chemically and physically homogeneous material prior to forming the constituents of the ceramic powder are combined using the method of mixing or blunging. Ceramic materials developed synthetically over the last several decades the term also refers to improvements in processing techniques that provide greater control over structures and properties of ceramic materials in general new ceramics are based on compounds other than variations of aluminum silicate which form.

Applications and processing of ceramics. Ceramic processing the higher performance of ceramics is the result of strict contr ol of purity composition microstructure and processing. Applications and processing of polymers. It is also important to add binders or plasticizers as well.

11 7 2 7 presinter thermal processing prior to firing ceramics often are heat treated at temperatures well below firing temperatures. Multiple choice questions applications and processing of metals and alloys. Multiple choice questions applications and. The purpose of ceramics processing to an applied science is the natural result of an increasing ability to refine develop and characterize ceramic materials.

Ceramic processing is used to produce commercial products that are very diverse in size shape detail complexity and material composition structure and cost.