Powder Injection Molding Ceramic Tooth

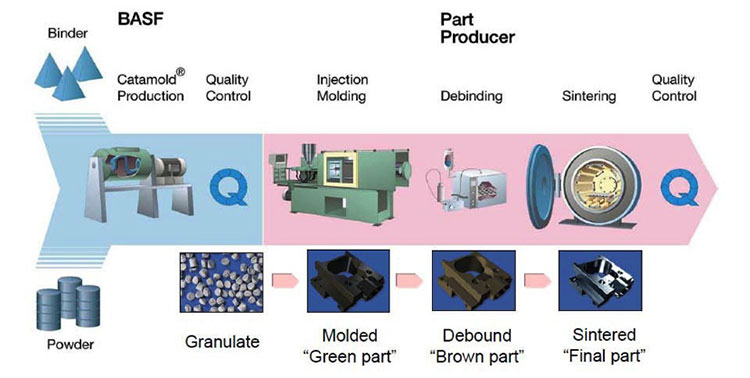

Powder injection molding of metal and ceramic parts 67 the starting material for pim usually termed feedstock is a homogeneous pelletized mixture of metal or ceramic powder and an organic multi component binder.

Powder injection molding ceramic tooth. Parts weighing from 0 1 g to 150 g. Injection molding green body production 3. In this method the ceramic powder is embedded in a wax carrier which will be overshot over a template or a mold made by 3d printing to form the ceramic part. Ceramic injection molding ceramic injection molding cim was first applied to manufacture the bodies of spark plugs in the 1920s.

Zirconias ytzp and mg stabilized. Our ceramic molding capabilities include injection molding and other manufacturing processes which allow us to provide finished parts to our customers exact specifications. Tolerances down to 1 2 of dimension or 0 0005. This process usually involves higher temperature and the template or the mold must be able to withstand molding temperature.

Ceramic injection molding is ideal for high volume production of complex tight tolerance components. Ceramic injection molding employs dependable equipment and advanced ceramic materials and compounds to produce ceramic components in a carefully controlled environment. By this way of manufacturing we can easily produce complex shaped cost effective components made of tungsten and molybdenum. It took 60 years before ceramic heat engine components were successfully shaped using the cim technique in japan an.

Ceramic injection molding is an innovative new process at indo mim under a six sigma controlled environment. General capabilities include the following. Certal solutions is a contract manufacturer of high quality precision ceramic and metal products fabricated using a high tech powder injection molding process. Mold cavitation from 1 to 10 parts.

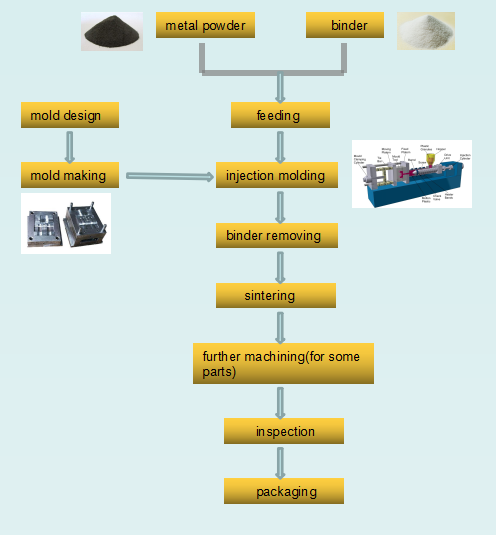

Some of the materials that we offer include. Thermal or solvent. However technology advancement for cim was slow. The technology consists of the following steps.

Cim is also a good option when you need to replace plastic and. Applications for powder injection molded parts besides lighting applications may be radiation shielding counterweights components in sports automotive aerospace medical and dental. The final result is a product of exceptional quality that meets not only a producer s high quality criteria but also strict quality and aesthetic standards specific to a. We serve the medical aerospace consumer automotive and electronics industries to name a few.