Porous Ceramics Processing

21 porous ceramic products can also.

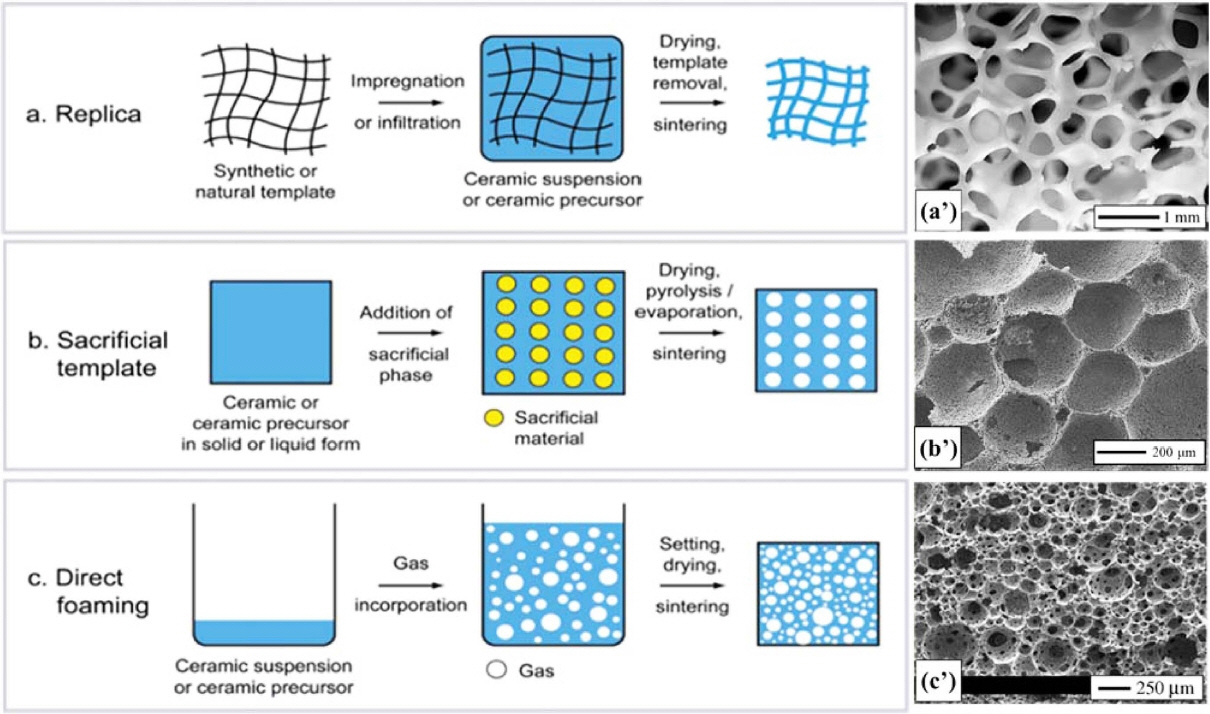

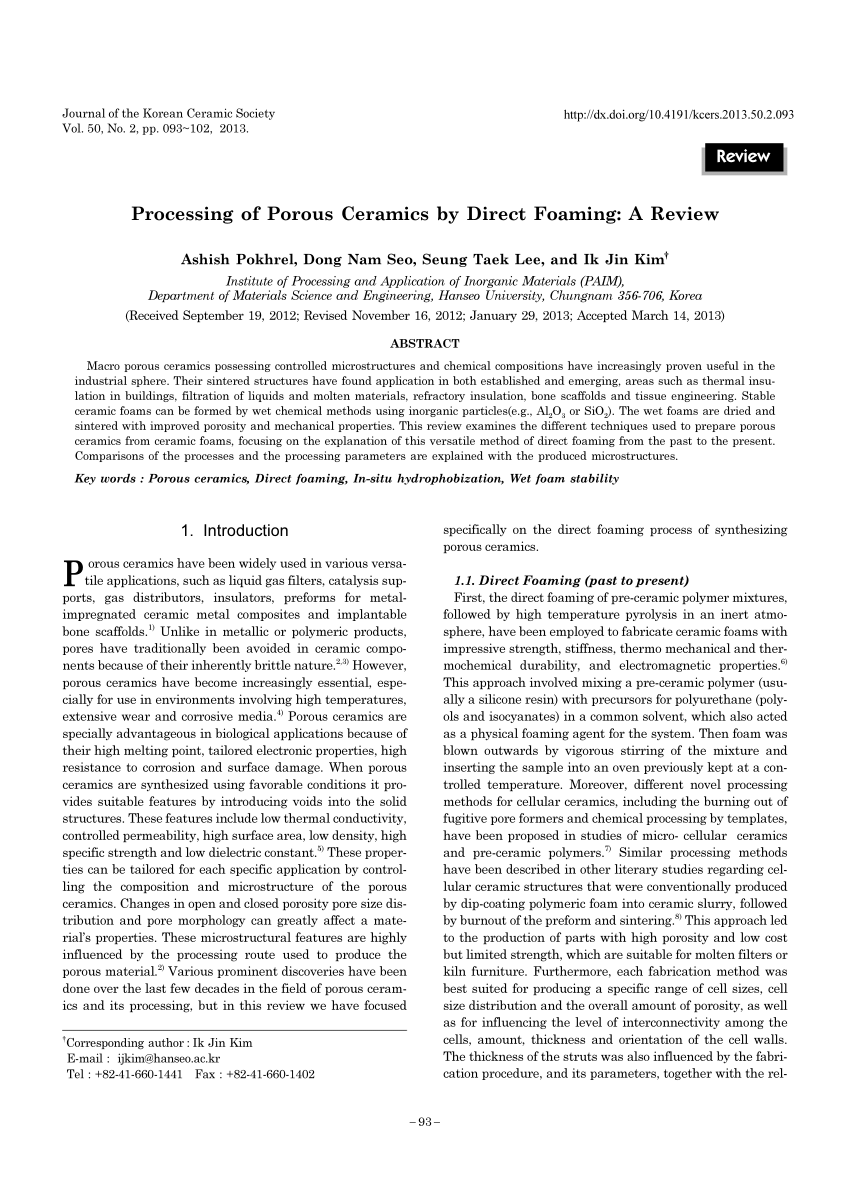

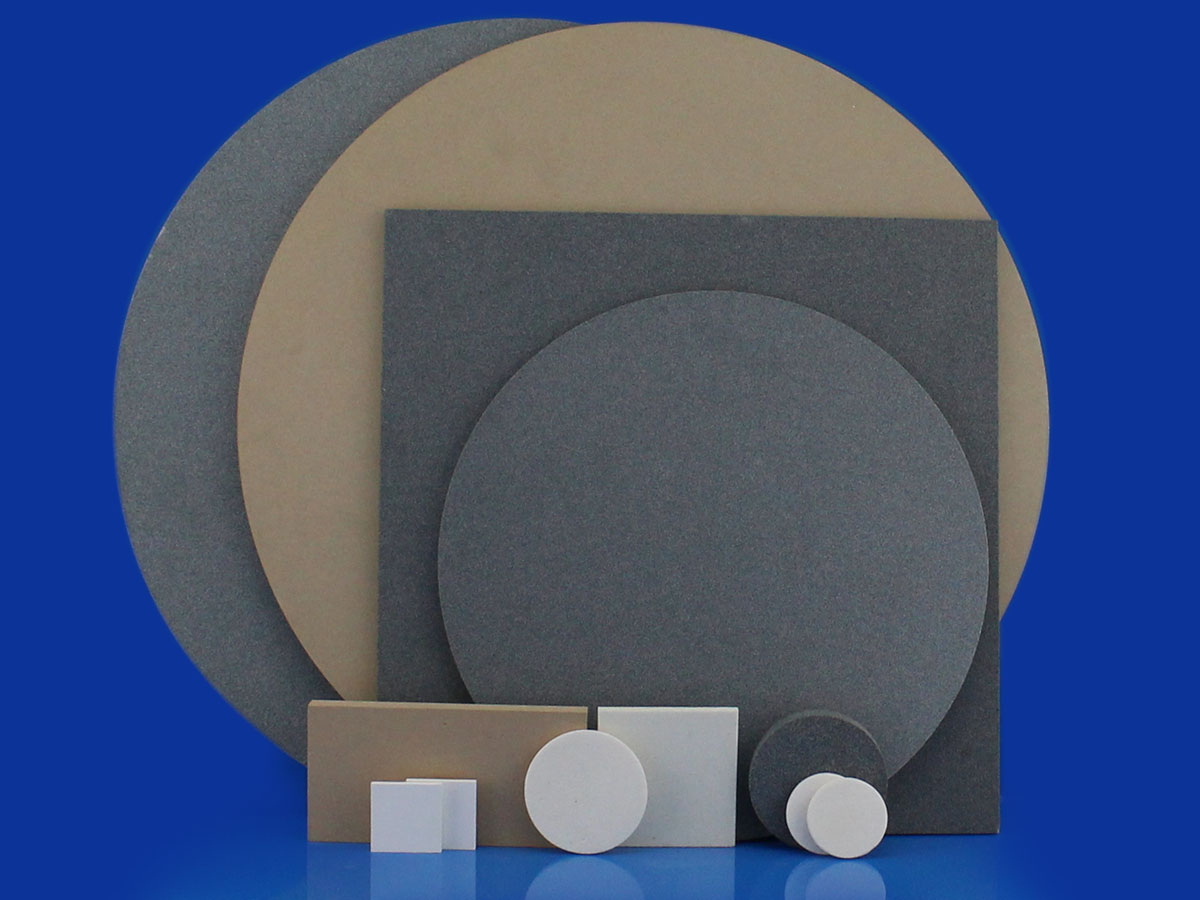

Porous ceramics processing. Porous ceramics with a well defined macroscopic shape and high mechanical stability can be fabricated by this novel processing route from powder which retains its intrinsic porosity 27 28. Porous ceramics are widely used in various versatile applications such as liquid gas filters catalysis supports gas distributors insulators preforms for metal impregnated ceramic metal composites and implantable bone scaffolds 1 2 unlike in metallic or polymeric products pores have been traditionally avoided in ceramic components because of their inherently brittle nature 3 4. Porous ceramics are utilized in a number of application sectors in order to mitigate several processing environmental biological or structural issues. The processes are divided into four categories including i partial sintering ii sacrificial fugitives iii replica templates and iv direct.

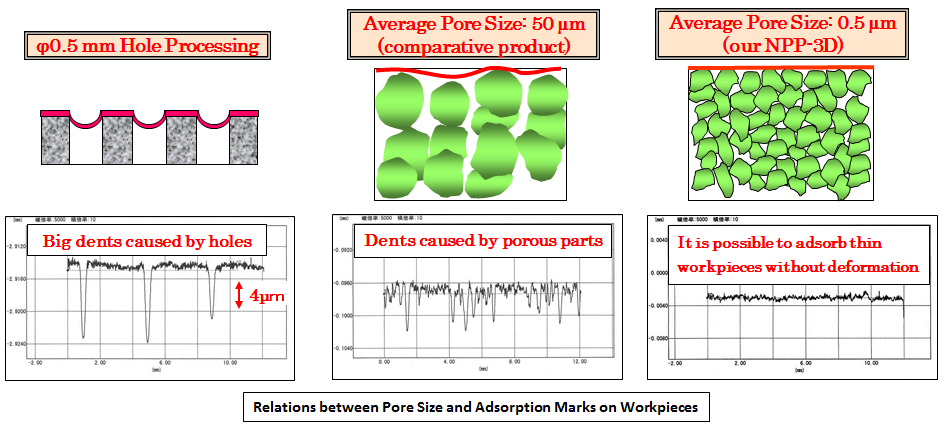

The range of innovcera porous ceramic filters are made from aluminum oxide and silicon carbide. On the basis of the fabrication process porous ceramics can have either open or closed pores or a combination of both. Custom coorstek porous ceramics can be tailored from 0 1 100 µm with precision tolerances and a variety of ceramic material options. Not only does the class of ceramic materials possess desirable properties but the nature and extent of the porosity in these components allows for the unique functionality and properties.

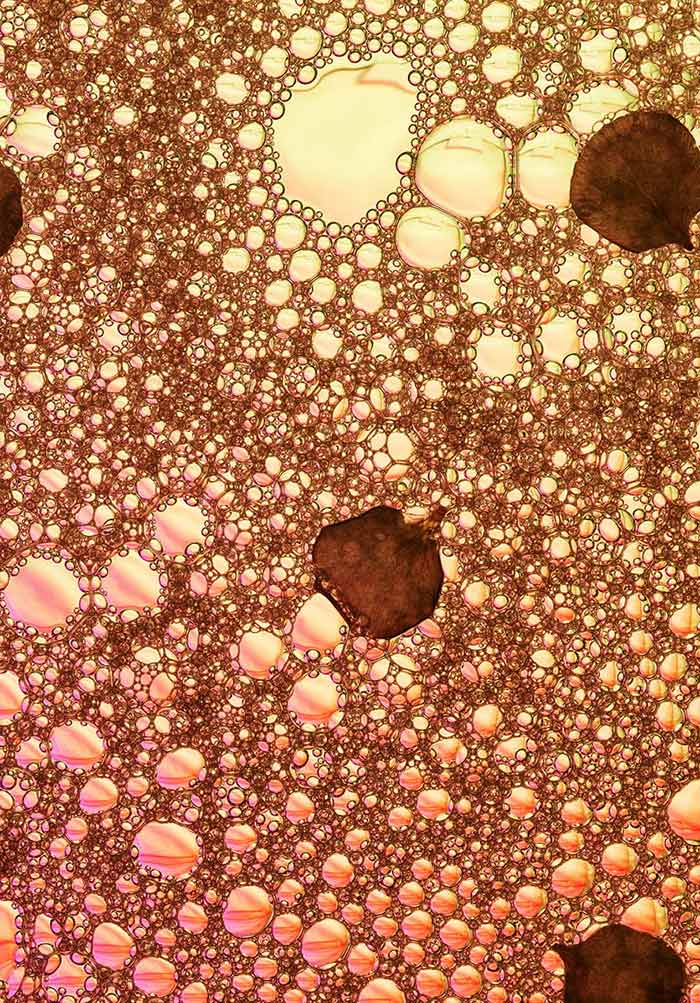

Porous ceramics have a wide range of uses in manufacturing across industries such as medical mining oil gas exploration alternative energy emissions control metal refinement chemical processing pharmaceutical printing wine making and other industries. The strong uniform porous ceramic has 40 50 open porosity with a tortuous pore structure and is available in pore sizes ranging from 6 to 90 microns. Some of its useful applications are in the manufacture of filter. Ceramic foam is an important part of porous ceramics and the open cell type of ceramic foam which is a new type of highly porous ceramics has a three dimensional reticulated structure with connective pores resulting in great specific surface area high fluid contact efficiency and a small loss of fluid pressure 26 27.

Porous ceramics are often used for chemical filtration and fluid separation. Followed by giving a general classification of porous ceramics a number of innovative processing routes developed for critical control of pores are described along with some important properties. The fields of application and specific forms of porous ceramics are wide and varied according to their manufacturing processes. Open pores are open at the surface and closed pores are isolated pores sealed from the surface.

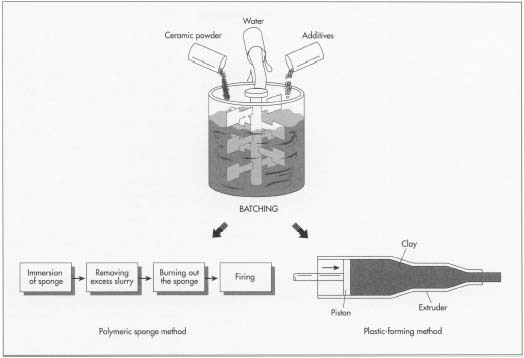

Schematic of porous ceramic processing methods.