Porous Ceramic Example Of Porous Materials

These materials composed of at least two phases like solid ceramic phase and the gas filled porous phase the gas content of these pores usually regulates itself to the environment as an exchange of gas with the environment is possible through pore channels.

Porous ceramic example of porous materials. For example porous piezoelectric ceramics show good piezoelectric property and are expected to be used for ultrasonic transducers etc. A ceramic is any of the various hard brittle heat resistant and corrosion resistant materials made by shaping and then firing a nonmetallic mineral such as clay at a high temperature. Some of the more common porous surfaces include laminate granite and various types of tile and plastic materials. 23 a variety of porous ceramics have been applied as materials for refractory bricks of kilns and furnaces in various industrial fields due to their low thermal conductivity and high thermal shock.

Ceramics are commonly used in construction consumer products vehicles scientific and industrial. 23 a variety of porous ceramics have been applied as materials for refractory bricks of kilns and furnaces in various industrial fields due to their low thermal conductivity and high thermal shock. One such material you might be familiar with is the silica gel pack used as a desiccant for food which consists of a ceramic material with minuscule holes pores for absorbing moisture. Hard surfaces are a combination of porous and nonporous materials.

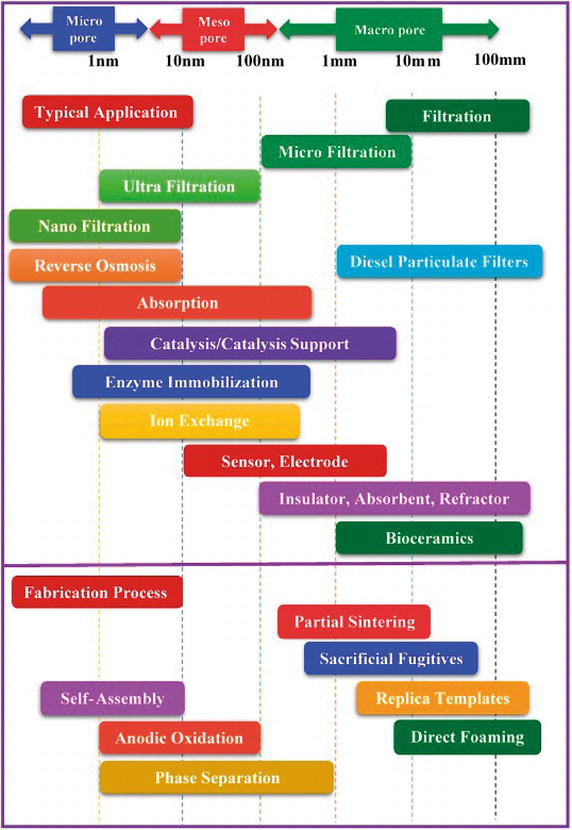

Porous ceramics are often used for chemical filtration and fluid separation. The crystallinity of ceramic materials ranges from highly oriented to semi crystalline vitrified and often completely amorphous e g glasses. Common hard surface materials are stainless steel solid surface laminate porcelain and a wide variety of tile and ridged plastic materials. Porous ceramics are categorized as those ceramics having high percentage porosity between 20 and 95.

Ceramics is a category of hard material that is typically manufactured by heating minerals. This predates the use of metal. At noritake we re conducting research and development on porous ceramic materials which shows fascinating properties because of the presence of pores. Humans have produced ceramics since at least 24 000 bc.

Custom coorstek porous ceramics can be tailored from 0 1 100 µm with precision tolerances and a variety of ceramic material options. Combining tightly toleranced pores with unique ceramic material properties enables applications not feasible before. Common examples are earthenware porcelain and brick.