Plunger Velocity Ceramic Injection Mold

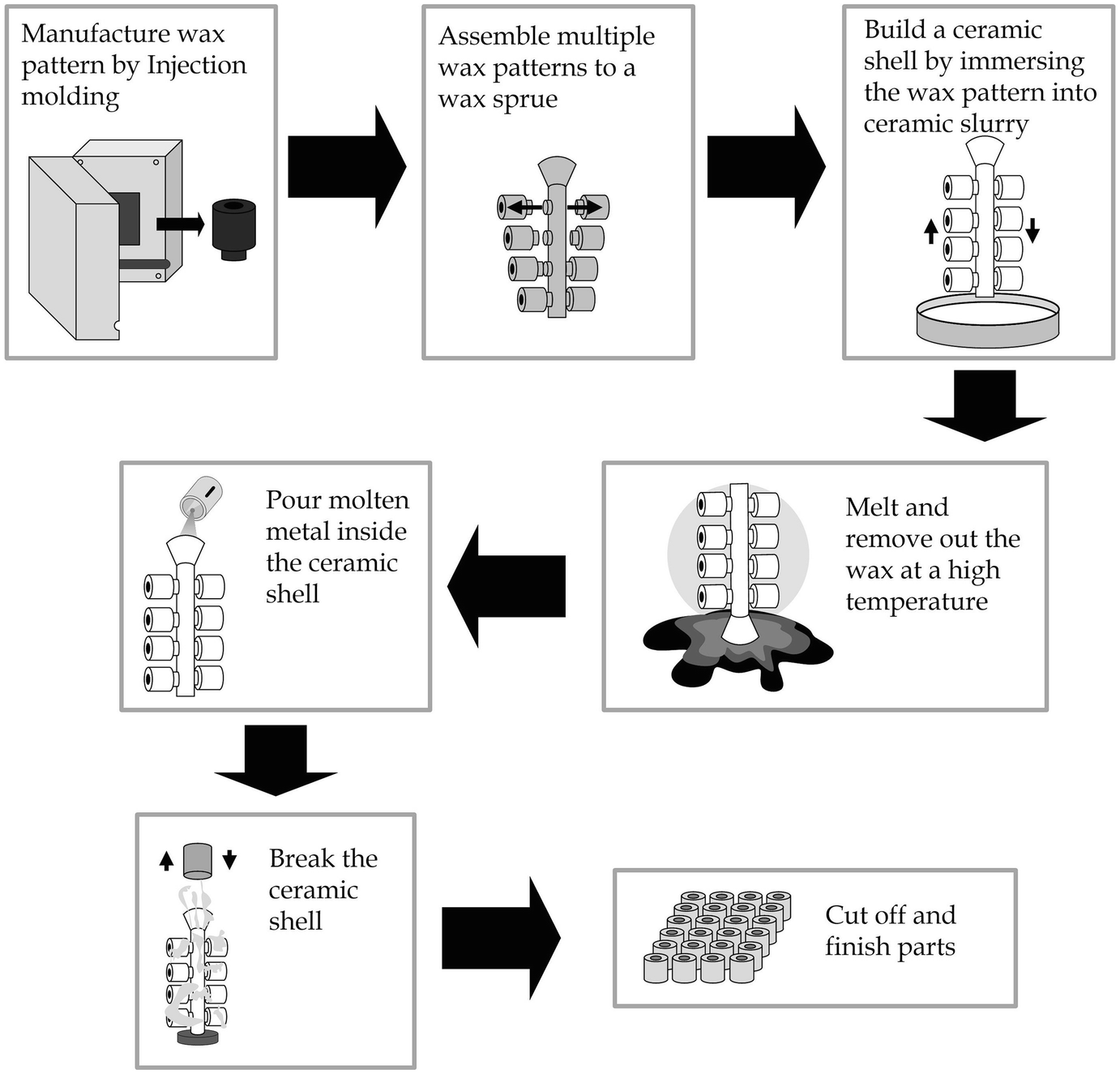

In injection molding a ceramic mix is forced through a heated tubular barrel by action of a screw or plunger.

Plunger velocity ceramic injection mold. Machining tool making repair injection molding size of facility. A linear encoder detects plunger position and a pressure sensor monitors injection pressure. This is achieved by a slight forward movement maximum 1 mm of the injection plunger. It is most common methods for manufacturing of plastics.

Once you have the graphics working to plot injection pressure vs. All copyright reserved by. 7595 innovation way mason oh 45040 phone. The injection molding process involve injecting or pressurizes a liquid plastic material into mold operation.

If your machine calls it a velocity the first thing you have to figure out is what pressure controls this pack velocity first stage set pressure or second stage pressure. 534 north 1st street cambridge oh 43725. The common injection molded plastics method is two. 513 754 8500 velocity concept development group cambridge.

Machining tool making repair injection molding size of facility. The plunger injection molding machine pushes forward the fused plastics in the charging barrel through the to and fro movement of plunger therein and the spreader further injects them into the mold cavity through the nozzle. Once the plunger injection movement is completed a holding pressure may be applied to the melt. The melton plastic may be as thermoplastic material and inject to image cavity part mould or die to take small time and product released by using ejector pin.

Injection molding is a manufacturing process for producing parts by injecting molten material into a mould or mold injection moulding can be performed with a host of materials mainly including metals for which the process is called die casting glasses elastomers confections and most commonly thermoplastic and thermosetting polymers. The plastication of plastics in the charging barrel mainly depends on the heat provided by the outer heater of charging barrel. It is called injection moulding. Time go to the screen on your controller that deals with pack or second stage velocity.

User selectable limits can be easily input on the process monitor screen. Oakley die mold. Plastic injection molding or injection molding machine is to make require shape by using mould include high pressurized melton plastic metal. Plunger type injection molding machines.

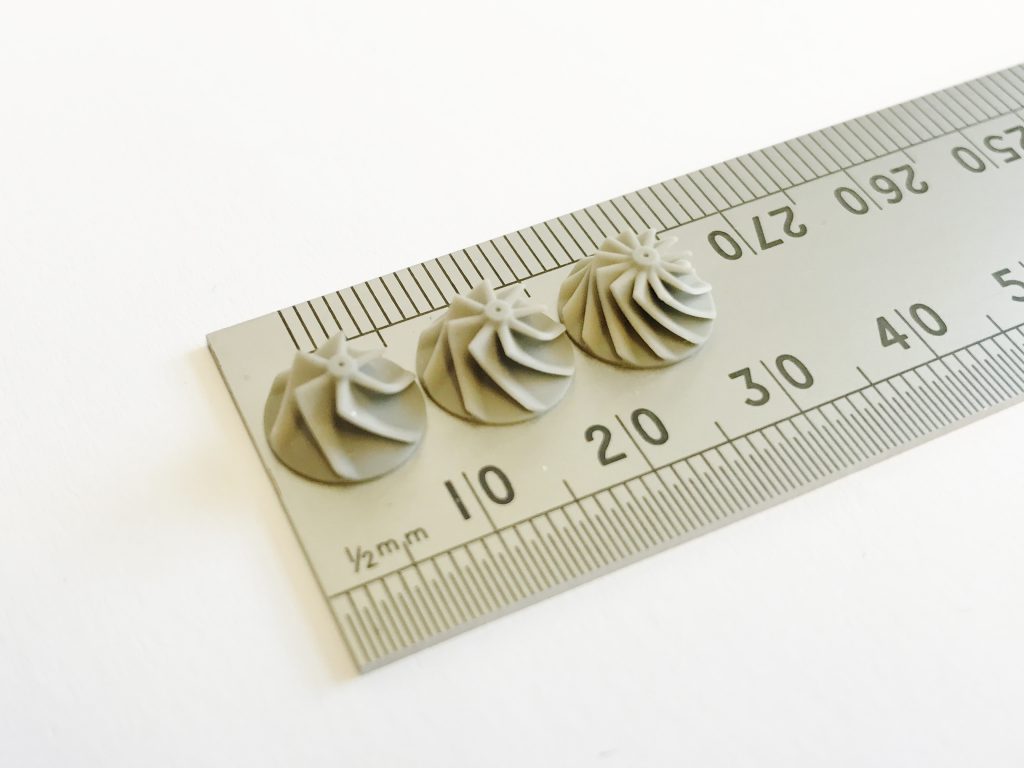

The mix consists of ceramic powder plus a thermoplastic polymer. The injection plunger then pushes the melt into the mold. The v line injection is controlled by a closed loop system which monitors actual speed vs. 24 000 sq ft address.

Other articles where injection molding is discussed.