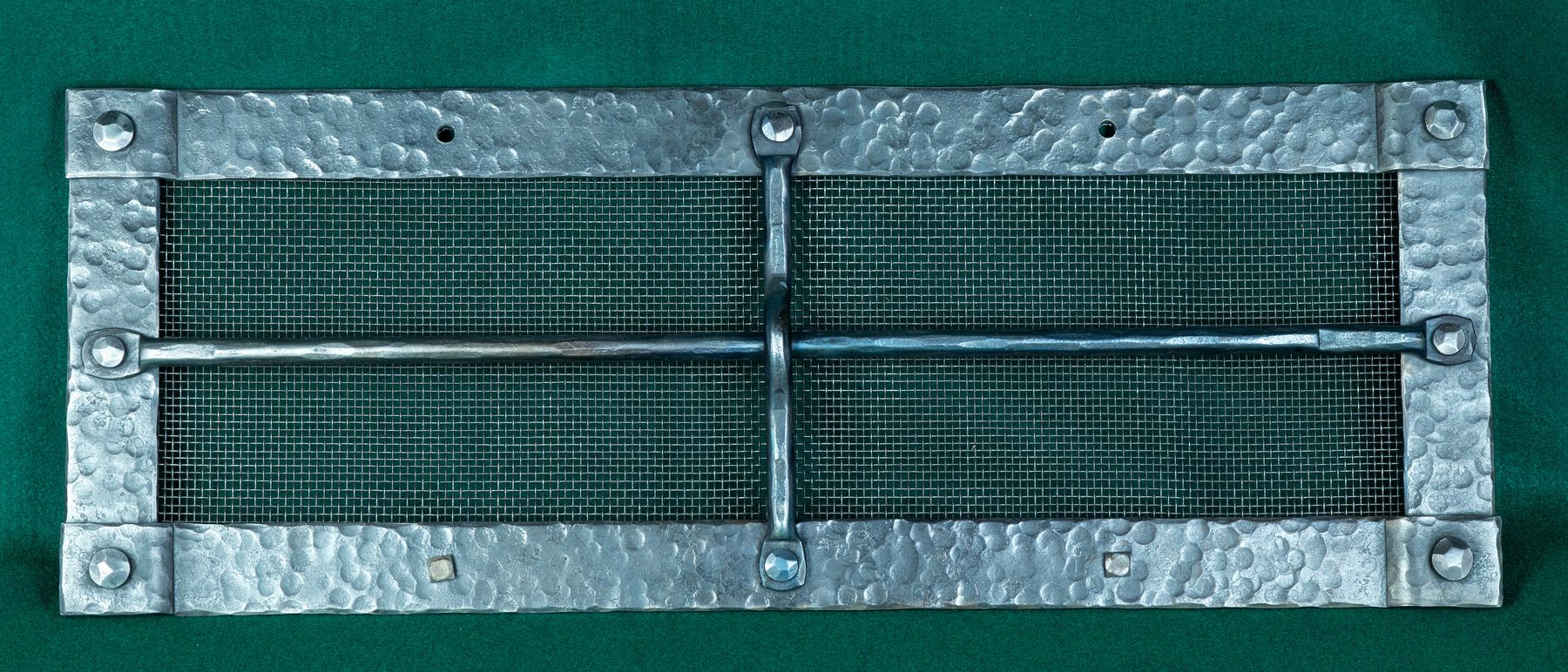

Pipe Weld Spatter Mat

Weld splatter resistant silicone rubber tubing silicone rubber tubing is available in 21 standard sizes and is usually always in stock.

Pipe weld spatter mat. Welding spatter is tiny pieces of molten metal and other weld contaminants jump away from the weld pool in the form of small hot globules. Weld curtains and screens form barriers to enclose hot work zones. Welding blankets curtains and screens keep spatter and sparks contained to prevent fires and damage. Try heavy duty nozzle dip gel to help keep welding tips from getting clogged.

If the qty shows in stock please note that the availability is subject to change dependent upon quantity ordered. To disconnect push on the release ring and pull the tubing out of the fitting. Made of flame resistant material these fittings are good for welding and other applications where sparks occur. Get your welders anti spatter at grainger where you ll find a wide range of products that can help protect mig welder parts and finished workpieces from welding spatter.

Tubing can be slit and then used as a wrap to cover wiring cables hoses using a tie wrap or stainless tie wrap to hold the tubing in place. They are made materials that resist flames and withstand heat generated by welding equipment. Resulting problems include spatter sticking to workpieces and equipment the required cleanup worker injuries and wasted material. Welding blankets drape over surfaces and equipment to provide a protective shield.

These globules then impact and stick onto cold surfaces. Request a quote for the weld spatter tubing you need on line today or contact polyconn for further information. Mig welding spatter sometimes called splatter comprises molten droplets of welding material. Catalog page pricing.

As weld spatter is often caused by cold a weld pool checking your mig welder for the right amperage or volts setting and wire feed speed for the metal and gauge you re welding is the first thing to do. Generated around the welding arc some droplets are expelled outside the weld puddle. Most welders have inside their cabinets or detailed in the operating manual a welding parameters chart. Onto the base metal you re welding your welding table and any surrounding it can get to in your workshop or garage.

Tubing discontinued to be replaced with spatter guard tubing. Welding fabrics for spark and fire protection. Whenever mig welding takes place spatter most likely occurs. They have good corrosion resistance.

When the molten droplets land and cool you re left with spatter. Compounding the situation is spatter that eventually builds up on the weld nozzle and contact tip causing them to have to be replaced. Our tubing catalog and price list are available on line.