Piling Mat Design Example

Piling platform piling mat design spreadsheet description.

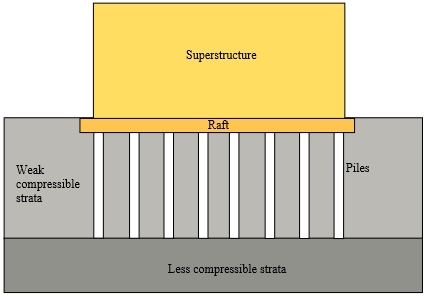

Piling mat design example. Pile foundation design in a student friendly manner. The term working platform is restricted to ground supported platforms constructed of granular material. Piling mats are a working platform used for construction plant such as piling rigs or mobile cranes. Via a relatively simple example it is demonstrated that additional pile forces and movements are developed in the piled raft as compared with the corresponding free standing pile group.

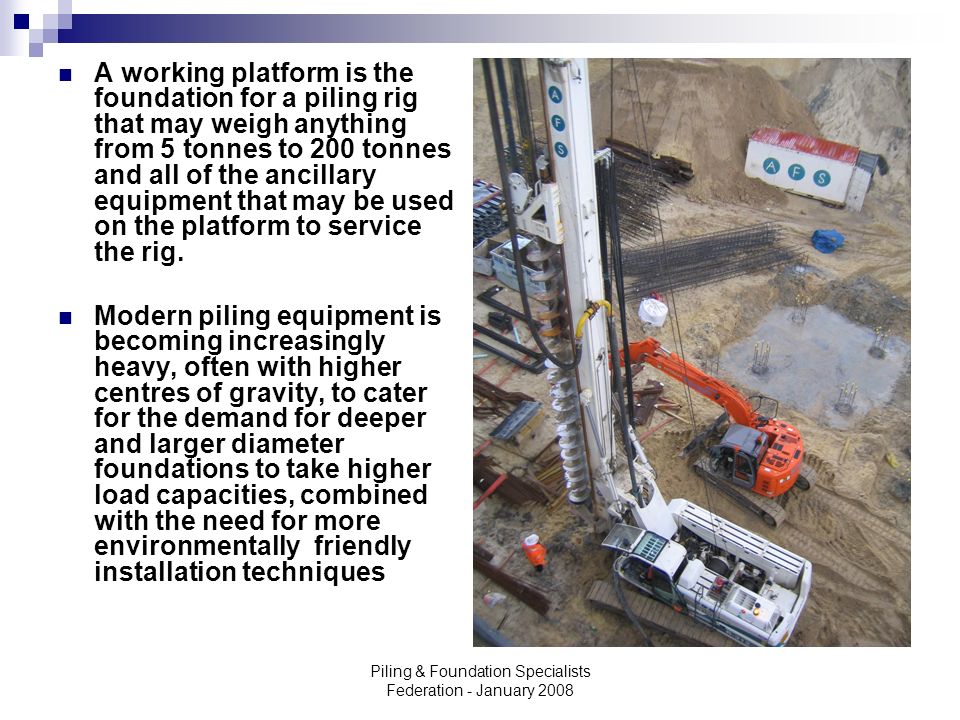

A piling mat is a type of working platform used for piling rigs to travel on providing a stable base on which they can move around the site and operate. Example a mat foundation is to be design by the conventional method rigid method for the loadings shown in fig. All columns are 40x40cm ultimate soil bearing pressure q ult 100kpa f yk 300mpa f yd 300 1 15 260 87 mpa c25 f ck 20mpa f ctk 1 5 mpa. A very helpful spreadsheet for designing working platforms for tracked plant piling platform for piling rig sheet piling rig handler or other ground treatment machinery.

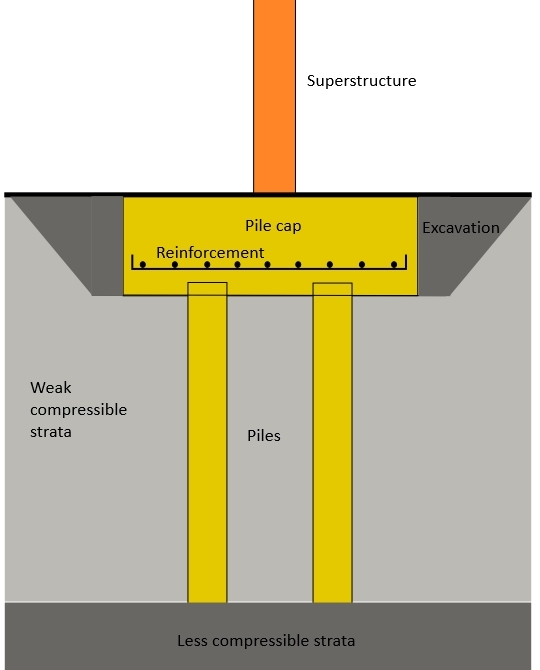

Allows to design working platforms with geosynthetic reinforcement commonly known as geogrids. This manual will be updated as changes in design and installation procedures are developed. Platform designed by idh. Instructional materials complementing fema p 751 design examples pile pier foundations view of cap with column above and piles below foundation design 29 passive resistance see figure 4 2 5 p y springs see figure 4 2 4 pile cap pile.

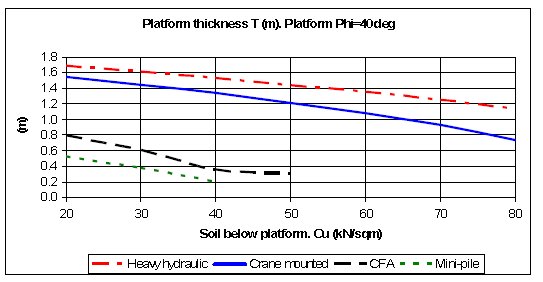

However this manual is intended to provide examples and procedures of proven technology. If a piling mat is too deep it will be incurring unnecessary. The design of the piling mat will depend on the ground conditions and loadings. Pile and pile group testing and development of more refined analytical models.

The design of piling mats will depend on the ground conditions and the piling equipment being used as well as the rig loadings which typically range from 5 to over 150 tonnes. The sub grade is generally characterised by undrained shear strength for cohesive soils or angle of shearing resistance for granular soils. Piling mats are typically constructed using well graded stone clean crushed concrete or crushed hard rock. They provide a stable base on which plant can safely travel and operate.