Partial Replacement Of Fine Aggregate With Ceramic Waste

Haider k ammash the possibilities waste glass of size up to 5mm as a fine aggregate in concrete.

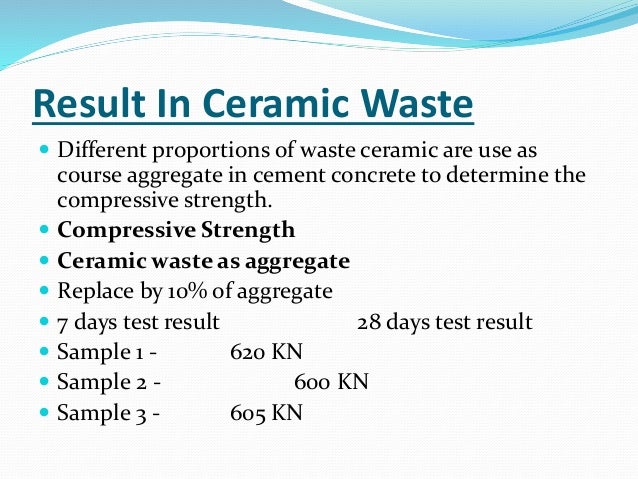

Partial replacement of fine aggregate with ceramic waste. Ceramic waste can effectively being used in concrete as a partial replacement of fine aggregate with the improved strength and durability. Then then from there it is noted that the continuous partial replacement would result. The ceramic waste crushed tiles were partially replaced in place of coarse aggregates by 10 20 30 40 and 50. The waste glass was used as a partial weight replacement of sand with percentages of 10 20 30 and 40.

Crushed waste ceramic tiles crushed waste ceramic tile powder and rebutted tyre waste are used as a replacement to the coarse aggregates and fine aggregate. They found that waste glass aggregate can be satisfactorily substituted for natural fine aggregate at replacement levels up to 20. Ceramic waste can be used as a partial replacement of cement or as a partial replacement of fine aggregate sand as a supplementary addition to achieve different properties of concrete. Conclusion using waste powdered ceramic tiles as partial replacement of fine aggregate workability decreased with increase in replacement level.

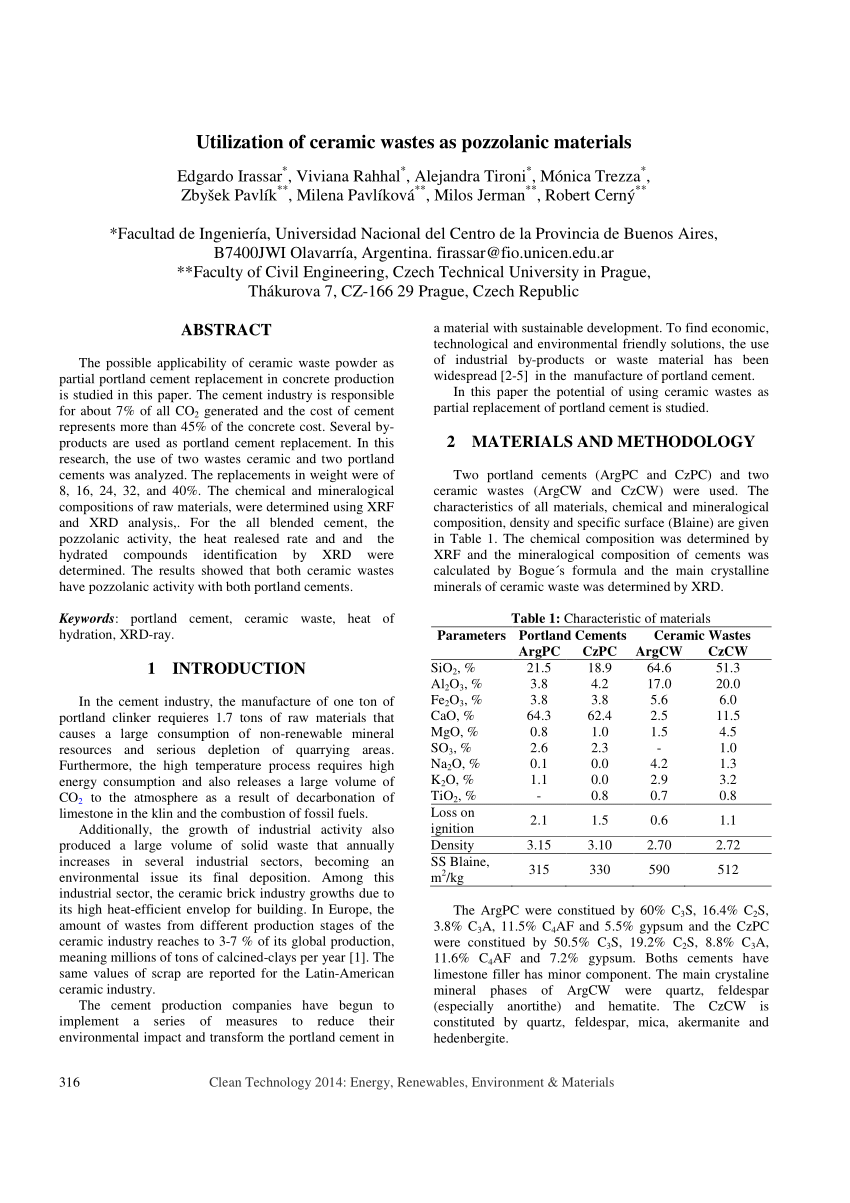

Hence the crushed waste ceramic tiles were used in concrete as a replacement for natural coarse aggregates with 0 5 10 15 20 and 25 of substitution. Introduction concrete is broadly used in creation of buildings bridges and other structures. The aim of this research is to evaluate the use of ceramic waste as partial replacement of coarse aggregates in the production of asphalt concrete. Ordinary portland cement cem i 42 5r complying with en 1971 8 provided.

The optimal replacement level of fine aggregate with powdered ceramic waste was found to be 30. 2 1 materials the concrete mix constituent materials were. To determine the physical properties of the coarse aggregates and ceramic wastes aggregates. To find a use of ceramic waste produced.

With partial replacement of fine aggregates by 5 of ceramic tile waste has also slightly increased by 11. Keywords ceramic waste fine aggregate replacement waste ceramic tiles. The aim of the study will be achieved through the following objectives. After analyzing results the optimum value of waste ceramic tile to be used within the concrete mix with a water cement ratio of 0 5 was determined as about 20.

Ceramic waste can be used as a partial replacement of cement or as a partial replacement of fine aggregate sand as a supplementary addition to achieve different properties of concrete. Of recycled ceramic tile waste aggregate. Ceramic tile waste replacement.