Oxidation Firing Ceramics Definition

Particles of iron pyrite that occur naturally in the clay melt and.

Oxidation firing ceramics definition. Dunting is the cracking or breaking of pottery inside the kiln usually after firing and caused by cooling too rapidly. With fuel burning kilns however care must be taken to ensure that the kiln does not go into reduction until the latter part of the firing usually the last half hour to the last hour and a half. C3h8 5 o2 4 h2o 3 co2. Your reaction breaks down to the following for an oxidation firing using propane.

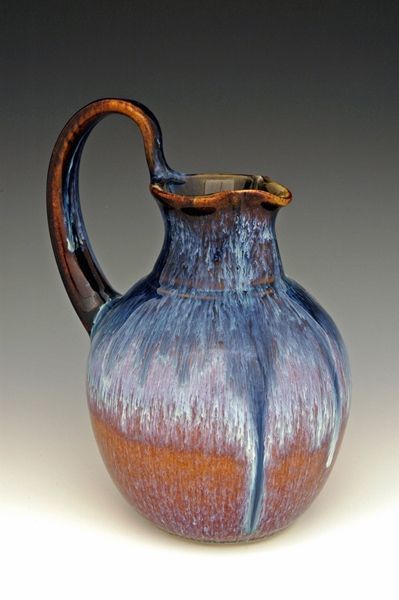

Oxidation firing in ceramics this term is most often used to refer to kilns firing with an atmosphere having available oxygen to react with glaze and body surfaces during firing. Reduction speckle a sought after visual effect that occurs in reduction fired stoneware. High fire porcelain or stoneware cone 02 to 1 degrees cone f c cone. Oxidation reduction salt wood raku oxidation firing is typically done in an electric kiln but can also be done in a gas kiln.

It is caused either by drafts of. Many high fire glazes are formulated for reduction and will not work successfully in neutral or oxidation firings these brilliant colorings and effects are created when metallic oxides in glazes change form. Electric kilns are naturally in an oxidation or neutral atmosphere. Fuel burning kilns give the artist control of how much or how little oxygen enters the firing chamber and when.

Oxidation firing definition oxidation firing is a technique used to oxidise ceramic materials. Fissura esquerda o fractura d argila durant l enfornada. Reduction firings can bring out some wonderful colors in pottery. A body clay with underglaze can be bisque fired at cone 4 to 6 then have a low fire glaze firing at cone 06 to 04.

High temperatures may be used or low temperatures. Raku definition is japanese hand modeled pottery that is fired at a low temperature and rapidly cooled. With access to enough oxygen to efficiently burn your fuel you are almost exclusively producing water vapor and co2 which will cause oxidation of your ceramic surfaces. It is the lack of oxygen in the last part of the process that is critical for the desired effects.

In this process ceramics heated at a certain temperature pull oxygen from the kiln chamber and this oxygen get combined with carbonaceous materials present in the ceramic body and thereby oxidize the ceramic materials. Oxidation firing allow very bright rich colors. Fisura agrietamiento o rotura de arcilla durante la cocción. Raku clay is usually bisque fired to cone 04 to 1 clays that are to have crystalline glazes should be bisque fired slightly higher than normal i e.

Oxygen is free to interact with the glazes when firing.